Barcoder 250 provides a gas cylinder tracking solution which is both robust and easy to use. The system uses the latest radio frequency technology (RFID) or protected barcode labels, to tag and uniquely identify cylinders as they are delivered to, and received back, from customers.

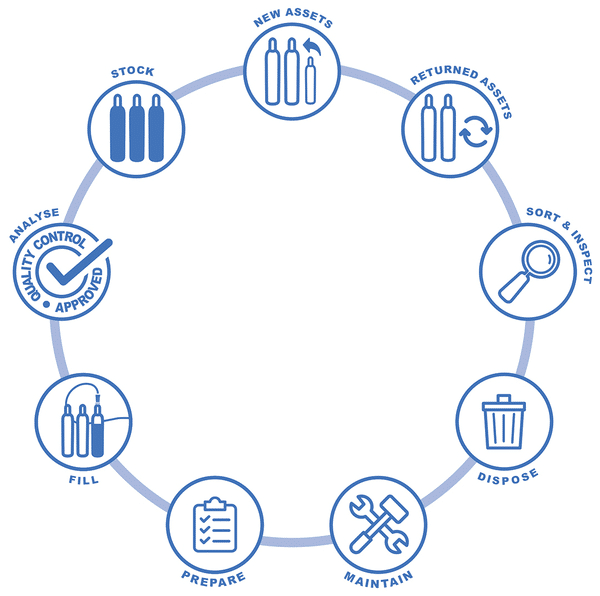

The gas cylinder tracking module enables companies to maximise the return on these expensive assets as well as delivering large efficiencies in the overall business process.

The cylinder tracking system is a special module within the Barcoder 250 system. This system integrates with Sage 50 Accounts and Sage 200 and therefore makes this technology available to a wide range of businesses. If necessary, the system can be integrated with the majority of other accounts packages, ensuring there is no requirement to change the existing accounting procedures.

The system is compatible with a range of Mobile PDAs including the CipherLab 9600 and the Psion Workabout Pro.

The gas cylinder tracking software module provides the following functionality:

Fundamental to the whole system is the selection of the most appropriate technology for identifying the individual cylinders. Barcoder 250 supports both barcode labels and RFID tags. The choice of technology depends in the environment the cylinders will be used in and the available budget.

The Barcoder 250 labelling solution is based on the GS1 barcode standard for returnable assets (GRAI). The system can print barcode labels to this standard. If it should be necessary the system can also regenerate barcodes if it is ever necessary to re label a cylinder because the label has become damaged or unreadable for some reason.

Barcoder 250 is also compatible with Trovan RFID transducers. These transducers are extremely durable and can withstand:

Trovan transducers can be read through the following

Trovan transducers have a very long life

The transducers provide over 500 billion combinations. Therefore, each cylinder will always be uniquely identified throughout the world.

The SageBarcoder system will ensure that duplicate cylinders cannot be added to the inventory.

The unique ID can never be erased.